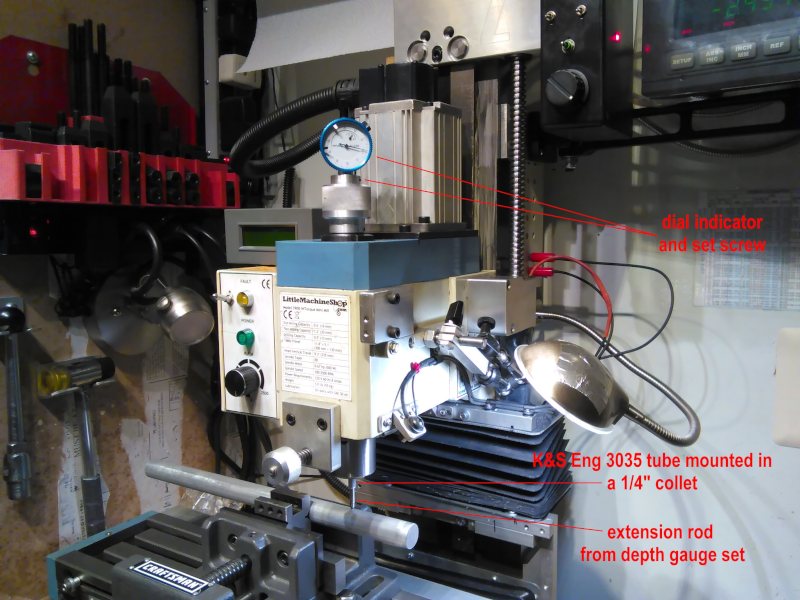

LMS 3900 Mods

Click above for newer

Extended Solid Column Pics

LMS 3900 Mods |

Click above for newer Extended Solid Column Pics | Mill Microscope with display - click for larger image |

|

I went to Lowes,

bought a 7/8"

Irwin Speedbor three flute boring tool.

They're made with a small helix starting point on the end and have

small points at the end of the flutes. Made for wood, it actually cut

the AL pretty easily. After lining up the Z mount and tightening the stock cap screws I began by drilling the 3/8-16 clearance hole (I decide to thru hole it with nylok nuts/washers inside the column - if I over torque/snap the bolt no big deal) I ground the pointy tips of the Speedbor off the flutes, and found a nylon spacer that was about 3/8 OD and just threaded onto the small starting point to act as the counterbore guide. Since the Z mount is only 0.400" thick the counterbore has to be shallow... therfore the hex head bolts needed to be faced down on the lathe. I happened to have some small OD washers that fit the 7/8" counter bore perfectly. Works well; during a controlled stall, the stepper now stalls and the Z mount does not move and the spindle head still clears the Z mount. |