Back to swarf page...

So I wanna be a Maker?

You gotta be fucking kidding me... again I point the reader to Mama I Wanna Be A Maker on Marketturd

After dealing with a typical 3D printer, I can't

believe that anyone would put up with this type of poorly

designed, amateurish bullshit for very long. Good Lord, they make these

out of 80/20 rail... that in itself smacks of hobbyist, No wait,

most hobbyists I know - guys that are TRUE CRAFTSMEN and can

run a lathe or a mill/CNC and make stuff to silly tight tolerance, know

how a LiPo works better than some engineers (can you say Samsung?), and

can actually BUILD SOMETHING - would puke at this shit

So I have to get/use one of these for a recent client... what a fucking nightmare. These things suck in many ways.

I

go to some U Boob channels and find some people that seem to know what

they're actually talking about.

The

one thing that got me was how many mentioned using something like

FireStop (used on range hoods for kitchen fires) since these have a

tendency of igniting. Just fucking great...

Most mention replacing the plastic

drive mechanism for the extruder with a nice aluminum one all pretty

and anodized...

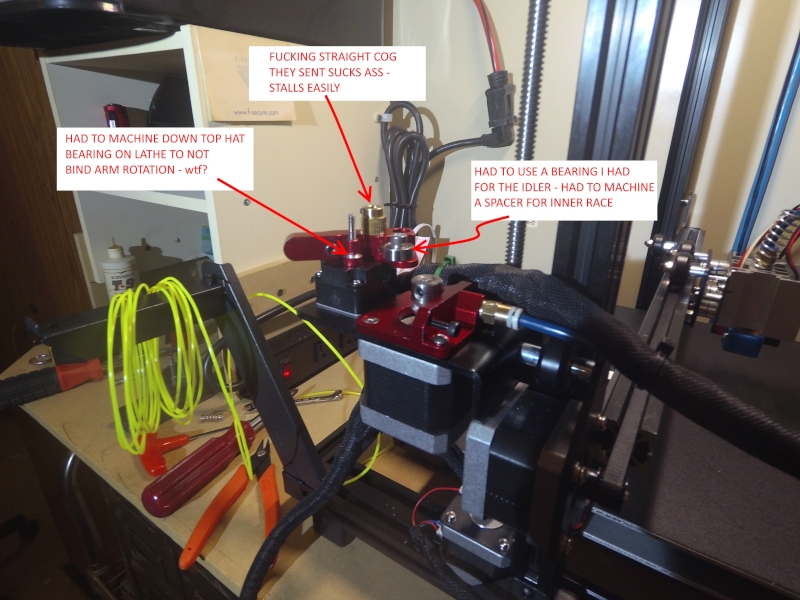

What a poorly executed design. As shown in the pics below - thank God I have a machine shop.

The

tophat for the left hand arm was so fucked that I needed to turn down

the brim to get it to not bind the arm. You can see where I lathed it

down...

Then I used the silly brass drive cog that came with

it... well that sucked - I was able to stall PLA with very little

finger pressure. What was worse was I had to alter a small gear

puller just to get the stock cog off the NEMA 17 motor shaft

So

I went back to the stock cog (which is concave) which means I wasted

time pulling it off - fucking great. Needless to say I used a small

boring tool to slightly enlarge the thing before reinstalling it on the

shaft (I ain't goin' thru the struggle of getting that off again).

So

since I went back to the original concave cog on the motor shaft, the

concave idler that came with the AL extruder drive kit wouldn't get

close enough to do shit. So I had to make a spacer for a bearing I had

in my shop spare parts bin work with the 4mm screw that secures

the inner race to the base plate. I used some AL tube I got from a

closed down hobby store ....

There's more shit I had to fix...

Back to swarf page...